PID 遙控小車

Homework Report Format

PID 遙控小車

- 應用與功能說明

- 自動修正路徑

- 藍芽遠端操控

- 設計考量與所需相關技術

- 操作方式:透過藍芽連線操控自走小車

- 移動方式:兩輪驅動

- 供電方式:電池或電腦USB

- 連線方式:WiFi或藍芽

- 方位感測元件:MPU6050

- 驅動裝置:DRV8833

- 系統方塊圖

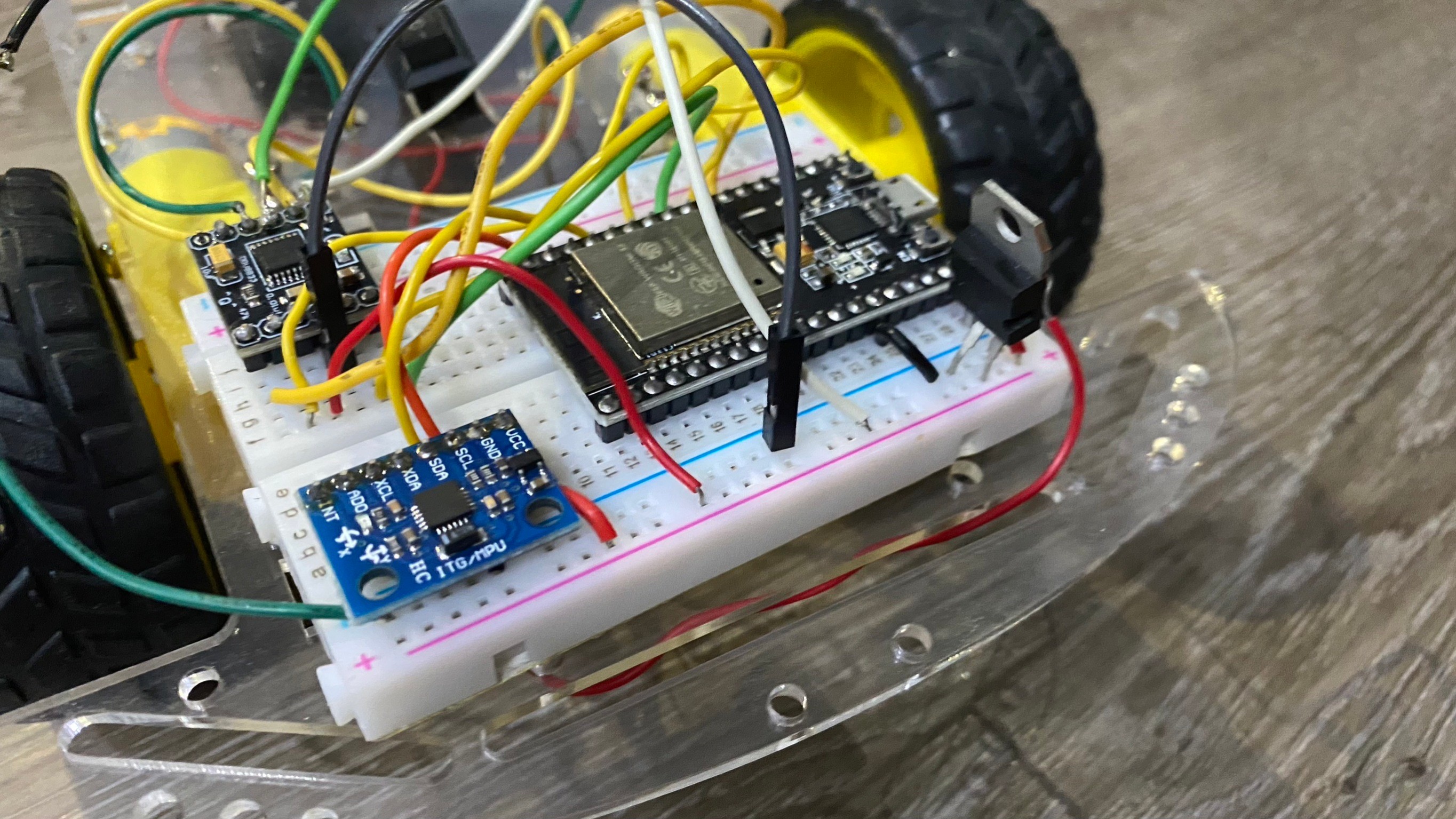

- 實作照片

- 位置偵測

- 實際操作

- 程式碼

//

// RoboCar with MPU6050 using PID control for going straight line

// by Richard Kuo, NTOU/EE

//

#include <Wire.h>

#include <ESP32MotorControl.h>

#include <MPU6050_6Axis_MotionApps20.h>

// MPU6050 : Inertial Measurement Unit

MPU6050 mpu;

//MPU6050 mpu(0x69); // <-- use for AD0 high

#define IN1pin 16

#define IN2pin 17

#define IN3pin 18

#define IN4pin 19

#define motorR 0

#define motorL 1

ESP32MotorControl motor;

// MPU control/status vars

bool dmpReady = false; // set true if DMP init was successful

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

// orientation/motion vars

Quaternion q; // [w, x, y, z] quaternion container

VectorInt16 aa; // [x, y, z] accel sensor measurements

VectorInt16 aaReal; // [x, y, z] gravity-free accel sensor measurements

VectorInt16 aaWorld; // [x, y, z] world-frame accel sensor measurements

VectorFloat gravity; // [x, y, z] gravity vector

float euler[3]; // [psi, theta, phi] Euler angle container

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

// packet structure for InvenSense teapot demo

uint8_t teapotPacket[14] = { '$', 0x02, 0,0, 0,0, 0,0, 0,0, 0x00, 0x00, '\r', '\n' };

static float preHeading, Heading, HeadingTgt;

// PID tuning method : Ziegler-Nichols method

const int Ku = 10;

const int Tu = 100;

const int Kp = 0.6 * Ku;

const int Ki = 1.2 * Ku / Tu;

const int Kd = 3 * Ku * Tu /40;

// PWM freq : NodeMCU = 1KHz, UNO = 500Hz

// PWM duty NodeMCU = 1023 (10-bit PWM), UNO = 255 (8-bit PWM)

#define PWM_FULLPOWER 1023

int USR_FullPower;

int USR_MotorPower;

int PID_FullPower;

int PID_MotorPower;

#define CMD_STOP 0

#define CMD_FORWARD 1

#define CMD_BACKWARD 2

#define CMD_RIGHT 3

#define CMD_LEFT 4

int command;

int angle;

// TB6612FNG : Full-Bridge DC Motor Driver

#define STBY D0

#define PWMA D3

#define AIN2 D4

#define AIN1 D5

#define BIN1 D6

#define BIN2 D7

#define PWMB D8

// value 1 or -1 for motor spining default

const int offsetA = 1;

const int offsetB = 1;

// Interrup Service Routine (ISR)

volatile bool mpuInterrupt = false; // indicates whether MPU interrupt pin has gone high

void dmpDataReady() {

mpuInterrupt = true;

}

void setup() {

Wire.begin();

Wire.setClock(400000);

Serial.begin(115200);

Serial.println("NodeMCU RoboCar with IMU");

motor.attachMotors(IN1pin, IN2pin, IN3pin, IN4pin);

motor.motorStop(motorR);

motor.motorStop(motorL);

mpu.initialize();

devStatus = mpu.dmpInitialize();

// initialize device

Serial.println(F("Initializing I2C devices...f="));

mpu.initialize();

// verify connection

Serial.println(F("Testing device connections..."));

Serial.println(mpu.testConnection() ? F("MPU6050 connection successful") : F("MPU6050 connection failed"));

// wait for ready

Serial.println(F("\nSend any character to begin DMP programming and demo: "));

/*while (Serial.available() && Serial.read()); // empty buffer

while (!Serial.available()); // wait for data

while (Serial.available() && Serial.read()); // empty buffer again*/

// load and configure the DMP

Serial.println(F("Initializing DMP..."));

devStatus = mpu.dmpInitialize();

// supply your own gyro offsets here, scaled for min sensitivity

// Note - use the 'raw' program to get these.

// Expect an unreliable or long startup if you don't bother!!!

mpu.setXGyroOffset(220);

mpu.setYGyroOffset(76);

mpu.setZGyroOffset(-85);

mpu.setZAccelOffset(1788);

// make sure it worked (returns 0 if so)

if (devStatus == 0) {

// turn on the DMP, now that it's ready

Serial.println(F("Enabling DMP..."));

mpu.setDMPEnabled(true);

// enable Arduino interrupt detection

Serial.println(F("Enabling interrupt detection (Arduino external interrupt 0)..."));

attachInterrupt(0, dmpDataReady, RISING);

mpuIntStatus = mpu.getIntStatus();

// set our DMP Ready flag so the main loop() function knows it's okay to use it

Serial.println(F("DMP ready! Waiting for first interrupt..."));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = mpu.dmpGetFIFOPacketSize();

} else {

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it's going to break, usually the code will be 1)

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

}

// read heading till it is stable

for (int i=0;i<200;i++) {

GetHeading(&Heading);

delay(100);

}

// set command & angle for moving RoboCar

command = CMD_FORWARD; // CMD_RIGHT

angle = 0; // +60

switch(command) {

case CMD_STOP:

USR_FullPower = 0;

PID_FullPower = 0;

break;

case CMD_FORWARD:

USR_FullPower = PWM_FULLPOWER * 3/4;

PID_FullPower = PWM_FULLPOWER - USR_FullPower;

break;

case CMD_BACKWARD:

USR_FullPower = PWM_FULLPOWER * 3/4;

PID_FullPower = PWM_FULLPOWER - USR_FullPower;

break;

case CMD_RIGHT:

USR_FullPower = PWM_FULLPOWER * 1/4;

PID_FullPower = PWM_FULLPOWER - USR_FullPower;

break;

case CMD_LEFT:

USR_FullPower = PWM_FULLPOWER * 1/4;

PID_FullPower = PWM_FULLPOWER - USR_FullPower;

break;

default:

USR_FullPower = 0;

PID_FullPower = 0;

break;

}

// set target heading to default heading

GetHeading(&Heading);

HeadingTgt = Heading + angle;

if (HeadingTgt>=360) HeadingTgt = HeadingTgt - 360;

else if (HeadingTgt<0) HeadingTgt = HeadingTgt + 360;

Serial.print("Heading Target = \t");

Serial.println(HeadingTgt);

}

void loop() {

const int Moving = 1;

if (!dmpReady) return;

// NOT USING MPU6050 INT pin

// wait for MPU interrupt or extra packet(s) available

//while (!mpuInterrupt && fifoCount < packetSize) {

//} // 100Hz Fast Loop

GetHeading(&Heading);

Serial.print("Yaw:\t");

Serial.print(Heading);

Serial.print("\t");

Serial.println(HeadingTgt);

PID(Heading,HeadingTgt,&PID_MotorPower, Kp, Ki , Kd, Moving);

USR_MotorPower = USR_FullPower; // assign User defined full power

Serial.print("Power:\t"); ;

Serial.print(USR_MotorPower);

Serial.print("\t");

Serial.println(PID_MotorPower);

if (Heading==HeadingTgt) PID_MotorPower = 0;

switch (command) {

case CMD_STOP:

motor.motorForward(motorR,USR_MotorPower - PID_MotorPower);

motor.motorForward(motorL,USR_MotorPower + PID_MotorPower);

break;

case CMD_FORWARD:

motor.motorForward(motorR,USR_MotorPower - PID_MotorPower);

motor.motorForward(motorL,USR_MotorPower + PID_MotorPower);

break;

case CMD_BACKWARD:

motor.motorForward(motorR,-USR_MotorPower - PID_MotorPower);

motor.motorForward(motorL,-USR_MotorPower + PID_MotorPower);

break;

case CMD_RIGHT:

motor.motorForward(motorR, USR_MotorPower - PID_MotorPower);

motor.motorForward(motorL,-USR_MotorPower + PID_MotorPower);

break;

case CMD_LEFT:

motor.motorForward(motorR,-USR_MotorPower + PID_MotorPower);

motor.motorForward(motorL, USR_MotorPower - PID_MotorPower);

break;

default:

motor.motorForward(motorR,USR_FullPower - PID_MotorPower);

motor.motorForward(motorL,USR_FullPower + PID_MotorPower);

break;

}

}

void GetHeading(float *Heading)

{

//calc heading from IMU

// reset interrupt flag and get INT_STATUS byte

mpuInterrupt = false;

mpuIntStatus = mpu.getIntStatus();

// get current FIFO count

fifoCount = mpu.getFIFOCount();

// check for overflow (this should never happen unless our code is too inefficient)

if ((mpuIntStatus & 0x10) || fifoCount == 1024) {

// reset so we can continue cleanly

mpu.resetFIFO();

Serial.println(F("FIFO overflow!"));

// otherwise, check for DMP data ready interrupt (this should happen frequently)

}

else if (mpuIntStatus & 0x02)

{

// wait for correct available data length, should be a VERY short wait

while (fifoCount < packetSize) fifoCount = mpu.getFIFOCount();

// read a packet from FIFO

mpu.getFIFOBytes(fifoBuffer, packetSize);

// track FIFO count here in case there is > 1 packet available

// (this lets us immediately read more without waiting for an interrupt)

fifoCount -= packetSize;

// display Euler angles in degrees

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

*Heading = int((ypr[0] * 180/M_PI)) + 180;

}//done

}//END GetHeading

void PID(float Heading,float HeadingTarget,int *Power, float kP,float kI,float kD, byte Moving)

{

static unsigned long lastTime;

static float Output;

static float errSum, lastErr,error ;

// IF not moving then

if(!Moving)

{

errSum = 0;

lastErr = 0;

return;

}

//error correction for angular overlap

error = Heading-HeadingTarget;

if(error<180)

error += 360;

if(error>180)

error -= 360;

//http://brettbeauregard.com/blog/2011/04/improving-the-beginners-pid-introduction/

/*How long since we last calculated*/

unsigned long now = millis();

float timeChange = (float)(now - lastTime);

/*Compute all the working error variables*/

//float error = Setpoint - Input;

errSum += (error * timeChange);

//integral windup guard

LimitFloat(&errSum, -300, 300);

float dErr = (error - lastErr) / timeChange;

/*Compute PID Output*/

*Power = kP * error + kI * errSum + kD * dErr;

/*Remember some variables for next time*/

lastErr = error;

lastTime = now;

//limit demand

LimitInt(Power, - PID_FullPower, PID_FullPower);

}//END getPID

void LimitInt(int *x,int Min, int Max)

{

if(*x > Max)

*x = Max;

if(*x < Min)

*x = Min;

}//END LimitInt

//

// Clamp a float between a min and max. Note doubles are the same

// as floats on this platform.

void LimitFloat(float *x,float Min, float Max)

{

if(*x > Max)

*x = Max;

if(*x < Min)

*x = Min;

}//END LimitInt

This site was last updated June 04, 2023.